Chapter 6.1 / Climate Change and the AT Industry

Climate Change and the AT Industry

This section focuses on the relevance of climate change to the apparel and textile industry. It describes how the industry contributes to climate change. The industry is changing in response to climate change. Students have a tremendous opportunity to be agents of change in the apparel and textiles industry.

Professional Development for Educators

Climate Change and the AT Industry

As an industry, apparel and textiles is one of the biggest GHG emitters on Earth because of its huge size and global scope. In 2015, the global apparel and textile industry had a total value of nearly 2 trillion US dollars (http://www.slideshare.net/Euromonitor/state-of-the-apparel-and-footwear-market-in-2015).

Many processes and products necessary for making fibers, textiles and apparel products consume significant quantities of fossil fuels. As a result, the apparel and textile industry accounts for approximately 10% of total carbon emissions (Zaffalon, 2010).

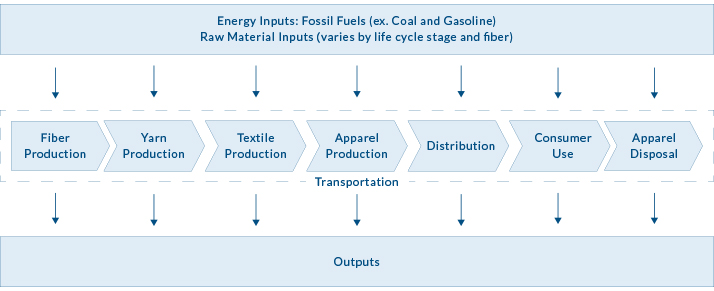

The following figure illustrates the apparel and textile supply chain with energy and raw material inputs recognized. It also indicates that there are outputs (such as solid and liquid waste and air pollution) at each stage.

Both the inputs and the outputs relate to climate change because of the GHG emissions associated with energy production and consumption in all stages.

Manufacturing of both textiles and apparel depends heavily on industrial machinery, typically powered through the burning of fossil fuels. Therefore the manufacturing of both textiles and apparel carries high energy demands.

A carbon footprint is the total amount of CO2 and other greenhouse gases (GHGs) emitted over the full life cycle of a process or product. It takes into account energy inputs and emission outputs throughout the whole supply chain from raw materials to processing, transport, final use, and disposal. A carbon footprint is measured by weight and usually reported in either tons or kilograms.

It is estimated that 60 billion kilograms of fabric are produced globally each year. This production requires 1 trillion kilowatt hours of electricity. Every Kilowatt hour of electricity produced by burning coal produces 900 grams of CO2 (Conca, 2012).

Additionally, the global non-profit organization, Business for Social Responsibility (2009) calculated aggregate clothing life cycle greenhouse gas emissions and determined the following:

- Fiber production accounted for 18% of total clothing greenhouse gas emissions

- Spinning accounted for 16%

- Consumer care for 39%

- Other stages along the supply chain accounted for between 1% and 7% each

Focus on the stages of fiber, yarn and textile production

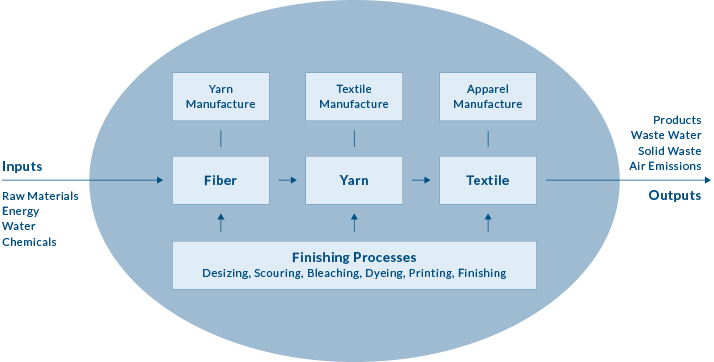

The following figure is similar to the previous figure, however it is more narrowly focusing on the stages of fiber, yarn and textile production.

This figure also includes the addition of the wet finishing processes of cleaning, dyeing, printing and finishing fibers, yarns and textiles, all of which are important processes to consider when examining climate change and the AT industry because these are energy intensive processes.

The carbon footprint associated with the spinning, knitting, dyeing, finishing, cutting and sewing required to manufacture 1kg of fabric can reach up to 12.5kg of CO2.

Compare this to the carbon footprint of steel which is about 2kg of CO2 per 1kg of steel (Zaffalon, 2010).

SELECTED Facts to consider regarding the Apparel and textile Industry's Carbon Footprint:

- The primary energy source within the manufacturing of AT remains fossil fuels.

- Many processes and products that go into making of fibers, textiles and apparel products consume significant quantities of fossil fuels.

- Annually the AT industry produces 60 billion kilograms of fabric, which consumes 1 trillion kilowatt hours of electricity (Zaffalon, 2010).

- In 2010 the electricity demands of the AT industry consumed 132 million tons of coal (Siegle, 2011).

- The production and consumption of a 100% cotton tshirt consumes 109MJ of energy in order to grow and process the cotton fibers, manufacture and dye the yarns, knit the textile, construct the tshirt, launder it 25 times, and incinerate it after consumer disposal (Allwood et al., 2006).

- China and India are both among the top textile and apparel manufacturing countries in the world.

- 66% of China’s energy comes from coal and 20% from oil (http://www.eia.gov/beta/international/analysis.cfm?iso=CHN).

- 55% of India’s energy comes from coal (https://en.wikipedia.org/wiki/Energy_policy_of_India)

- China and India combined are responsible for 54% of global consumption of coal (US Energy Information Administration, 2013 http://www.eia.gov/pressroom/presentations/sieminski_07252013.pdf

In the Classroom

Climate Change and the AT Industry

ACTIVITY: Carbon Footprint Slides to use with Carbon Footprint Activity Climate Change and the AT Industry - 6.1 - PowerPoint PresentationMore Information and Resources

Climate Change and the AT Industry

- Forbes Report from United Nations introducing risks and opportunities for business: Climate Change Threatens Economic Growth- How Should Investors React http://www.forbes.com/sites/mikescott/2014/04/03/climate-change-threatens-economic-growth-un-report-how-should-investors-react/

- CBS Money Watch Business leaders say climate change threatens economy http://www.cbsnews.com/news/business-leaders-say-climate-change-threatens-economy/

- Bloomberg Business Which Sectors are most at Risk from Climate Change? http://www.bloomberg.com/news/videos/b/57b8dd7f-d120-4947-8fe8-f48154297c23

- ABC Landline Climate Change and Agriculture http://www.abc.net.au/landline/content/2013/s3682086.htm

- ABC Landline Wool Revival http://www.abc.net.au/landline/content/2015/s4258864.htm

- Climate Change Pledge by leading apparel companies in response to COP21 http://www.ceres.org/files/apparel-statement/at_download/file

References

- Allwood, J.M., Laursen, S.E., de Rodríguez, C.M., & Bocken, N.M.P. (2006). Well dressed? The present and future sustainability of clothing and textiles in the United Kingdom. Cambridge, UK: University of Cambridge, Institute for Manufacturing.

- Business for Social Responsibility. (2009). Apparel industry life cycle: Carbon mapping. [Online] Available: http://www.bsr.org/reports/BSR_Apparel_Supply_Chain_Carbon_Report.pdf

- Conca, J. (2012). How deadly is your kilowatt? We rank the killer energy sources. Forbes Available: http://www.forbes.com/sites/jamesconca/2012/06/10/energys-deathprint-a-price-always-paid/

- Siegle, L. (2011). To die for: Is fashion out of this world? London, UK: Fourth Estate.

- Zaffalon, V. (2010). Climate change, carbon mitigation, and textiles. [Online] Available: http://www.textileworld.com/Issues/2010/July- August/Dyeing_Printing_and_Finishing/Climate_Change-Carbon_Mitigation_And_Textiles